Disruption and shut down times are minimised due to the rapid nature of 3D laser scan capture. Site surveys are completed many times quicker than by using conventional survey techniques.

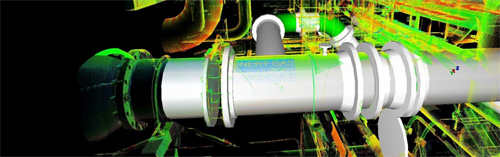

Our clients are able to take virtual tours of the site / facility from the comfort of their office. The scan data can be accessed via the Internet and the photorealistic; colour point clouds can be freely interrogated. Measurements can be made quickly and easily as and when required without the need for return visits.

Repeat site visits are virtually eliminated as the scanner captures everything.

Similarly, the laser scan is almost always larger than the survey required so a specification could be added to later without the need for a return visit.

Hybrid surveys combining laser scanning with total station surveys can be created which allow for the best of both worlds.